Boiler Technology / Case Studies

Eutectic Cast Iron Means Strength

De Dietrich R&D developed a new eutectic cast iron in 1980 and it quickly became the highest reference in cast iron metallurgy.

The word “eutectic” means that the melting point temperature of the cast iron is lower than the melting point temperature of all of the components included in its manufacture.

In operation, eutectic means strength:

- Homogeneous cast iron results in greater structural integrity

- The highest standard in resistance to corrosion allows no weak points or pitting corrosions

- The ability to withstand low water temperature input creates longer boiler life

- Time and money are saved through easy cleaning and maintenance

Flexible Cast Iron Creates Longer Operating Life:

Thanks to the most modern processes and the high quality of its eutectic cast iron, De Dietrich manufactures the most flexible cast iron in the world. Its modulus of elasticity is 30% greater than any other cast iron currently available.

The bottom line result of De Dietrich in depth experience is:

- Extended boiler-operating life

- Savings in time, money and fuel consumption

- Greater boiler efficiency

- Reduced costs for equipment maintenance and replacement

Efficiency Greater Than 88% Saves Money:

Supported by powerful computers in state-of-the-art equipped laboratories, the De Dietrich Research and Development Department designed an optimized cast iron section that achieves full heat transfer through:

- 3 & 4 pass fire chamber design

- Optimized fins that permit greater heat transfer and combustion efficiencies greater than 88%

- Fire box totally surrounded by system water

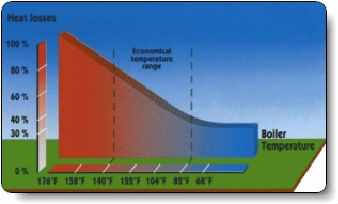

Low Modulated Temperature Produces Extraordinary Annual Efficiency:

By using indoor/outdoor reset, De Dietrich boilers can modulate to lower temperatures than all other cast iron boilers. The result: extraordinary annual efficiency as well as greatly increased control and ease of

installation.

Boiler temperatures can go down to 85° F for the GT 300 series and 105° F for the GT 400 and GTE 500 series without damage to the castings. The design and quality of the cast iron provide control and operating efficiency, thus assuring lower operating costs and longer life. Low operating temperature capabilities make the GT series ideal for water to air heat pumpor 2 pipe systems.

Highest quality Insulation Minimizes Heat Loss:

In order to achieve its very high annual efficiency, De Dietrich boilers are equipped with a minimum thickness of four inches of reinforced fiberglass wool insulation around all combustion/furnace areas of the boiler. Heat losses are therefore reduced to the minimum possible.

Low NOx Emissions Consider the Environment:

The future demands careful energy management that protects our environment. De Dietrich’s state-of-the-art design allows easy application of low NOx and CO emission burners. This will become even more important as we enter the next century.

Up to 91 PSI Working Pressures Maximize Your Flexibility:

De Dietrich boilers meet ASME requirements and rate far above other industry

standards.

On special-order commercial and industrial boilers, the maximum working pressures of our boilers can go to 60 PSI for the GT-200A series, up to 81 PSI for the GT-300A series, up to 91 PSI for the GT-400A series and up to 83 PSI for the GTE-500A series. Your bottom line benefit: greater versatility and flexibility of application for both hydronic heating and process systems.

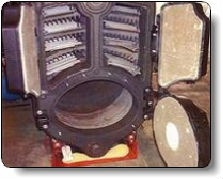

Easy Maintenance and Cleaning Save Dollars:

De Dietrich boilers are supplied with high quality, removable, full-swing doors that give access to all flue ways and combustion areas for easy maintenance and cleaning without burner removal. De Dietrich's boilers are also enhanced by removable cast iron turbulators (baffles).

BiSpherical Push Nipple Assembly Ensures Perfect Fit:

Bi-Spherical push nipple assembly of De Dietrich boilers translate into longer life, easier quicker assembly of sections, and higher operating pressure. Machined to very close tolerances, their exceptionally tight fit produces both safety and reliability.

Siliconed Thermocord Prevents Flue Gas Leakage:

A siliconed thermocord is sandwiched between sections to provide the perfect tightness necessary to prevent leakage of flue gas. This careful attention to engineering increase safety and extends the perfect operation of the boiler for many years.

Contact Us at:

DDR Americas 1090 Fountain St. N., Unit 10, Cambridge, Ontario, Canada N3E 1A3

© 2005-2013 DDR Americas, All Rights Reserved. | Terms of Use | Privacy